Blog

Top 10 Pressure Data Loggers You Need to Know About?

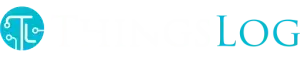

In the world of data collection, the pressure data logger stands out as a vital tool. As Dr. Emily Carter, a leading expert in the field, aptly states, "Pressure data loggers provide insights that can’t be ignored." These instruments are crucial for various industries, from manufacturing to environmental monitoring.

Pressure data loggers help capture minute changes in pressure over time. This data can be vital for ensuring the safety and efficiency of processes. However, despite their importance, many overlook the complexities involved in selecting the right model. Not all pressure data loggers are created equal, and the best choice depends on specific needs.

Yet, potential users often face challenges. Understanding the features and specifications of each model can be daunting. Wouldn't it be easier if all options were straightforward? Still, with a solid grasp of what to look for, anyone can find the right pressure data logger for their needs.

Overview of Pressure Data Loggers and Their Importance

Pressure data loggers play a vital role in various industries. They help monitor pressure fluctuations in real-time. This can be crucial for ensuring safety and efficiency. These devices collect data over time, providing valuable insights into operational processes.

Understanding how these loggers work is important. They often use sensors to measure pressure changes. The collected data can reveal patterns and anomalies. For instance, a sudden spike in pressure may indicate a potential hazard. However, interpreting this data can be challenging, requiring careful analysis. The quality of data also depends on calibration and environmental conditions.

The importance of pressure data loggers cannot be overstated. They help prevent equipment failures and downtime. Moreover, they support compliance with industry regulations. Although they are essential tools, selecting the right one can be overwhelming. Factors such as accuracy, range, and storage capacity must be considered. Using these devices effectively involves ongoing learning and adaptation.

Key Features to Consider When Selecting a Pressure Data Logger

When selecting a pressure data logger, several key features should be kept in mind. Accuracy is paramount. A reliable logger must provide precise pressure readings. Calibration is also crucial. Regular calibration ensures data integrity over time. Consider the logger's measurement range. It should align with your specific needs, whether for low, medium, or high pressures.

Data storage capacity is another significant factor. A logger with ample storage can capture long-term trends. Look for models that offer easy data export options too. This facilitates analysis and reporting, making your job easier. User-friendly interfaces can save time and reduce errors. Intuitive menu systems make navigation straightforward.

Finally, examine durability. Will it withstand harsh environments? If your settings are extreme, rugged construction is vital. Waterproof and shockproof features may be necessary. Don't overlook battery life either. Frequent recharging can disrupt operations. Be mindful of these attributes as you choose the right pressure data logger for your applications. Each decision influences data quality and reliability.

Top 10 Pressure Data Loggers: A Comparative Analysis

When it comes to pressure data loggers, choosing the right one is crucial for accurate readings. The market is saturated with options. However, key features differentiate these devices. For instance, data collection frequency, accuracy, and operational range are vital. A recent industry report indicated that accuracy can vary by as much as 5% among various models. This variance can significantly impact data integrity in critical applications.

Another essential aspect is the durability of these devices. Many pressure loggers are designed to withstand harsh environments. Yet, not all perform equally. In fact, a study found that over 25% of low-cost models fail in extreme conditions. Users must consider long-term reliability alongside cost. Selecting a model with advanced materials can vastly improve performance.

Battery life also merits attention. Some pressure data loggers last for weeks, while others may fail within days. The average operational lifetime reported varies between 40 to 100 hours. Users often overlook this feature, leading to inconvenient downtime. In conclusion, having a comprehensive understanding of these parameters will help in selecting a suitable pressure data logger.

Applications of Pressure Data Loggers Across Industries

Pressure data loggers are essential across various industries. They provide vital measurements that help monitor and control processes. From manufacturing to healthcare, these devices play a crucial role. For instance, in the food industry, monitoring pressure during production ensures safety and compliance. A recent industry report indicated that nearly 70% of foodborne illnesses are preventable with adequate monitoring.

In the oil and gas sector, these loggers track pressure changes in pipelines. Accurate readings can prevent leaks and enhance safety. Data suggests that improper pressure management costs the industry billions annually. Refining operations depend on consistent pressure data for product quality. These loggers are not just useful; they are necessary for operational efficiency.

Tips: Make sure to calibrate your pressure logger regularly. This ensures accurate readings and prevents costly errors. Also, consider using loggers with alarm features. These alert operators to critical changes in real-time. Additionally, maintain a log of all measurements. This will help in identifying trends and addressing potential issues earlier.

Maintenance and Calibration Tips for Pressure Data Loggers

When it comes to the reliability of pressure data loggers, maintenance and calibration serve as crucial practices. Regular checks ensure accurate readings. According to a recent industry report, up to 15% of pressure data loggers experience calibration drift over time, affecting the precision of collected data. This emphasizes the importance of establishing a calibration schedule.

Calibrating pressure data loggers involves using reference standards. These should be traceable to national or international standards. It’s common for professionals to forget this vital aspect. Effective calibration can require specific environmental conditions. Failing to maintain these conditions may lead to misleading results.

Furthermore, performing routine maintenance is often overlooked. Dust and moisture can hinder performance. Regular cleaning and inspections help lengthen the lifespan of the devices. One phase of maintenance that receives less focus is the housing integrity. Cracks can lead to serious inaccuracies. Professionals often express regret about underestimating these small details. Ensuring operational reliability requires diligence and attention to these factors.

Top 10 Pressure Data Loggers You Need to Know About

This bar chart displays the precision and calibration frequency of top pressure data loggers, showing their performance characteristics essential for maintenance.

Related Posts

-

Best Digital Water Meters for Accurate Consumption Tracking and Easy Monitoring

-

2025 Top 10 Data Loggers You Can't Miss: Ultimate Buying Guide

-

Top 10 Benefits of Fuel Tank Monitoring Systems for Efficient Fuel Management

-

How to Use LoRaWAN Sensors for Efficient IoT Solutions

-

Top 5 Benefits of Using WiFi Water Meters for Smart Water Management

-

2025 How to Optimize Your Tank Level Monitoring System for Maximum Efficiency